Camber’s Vertical Advantage

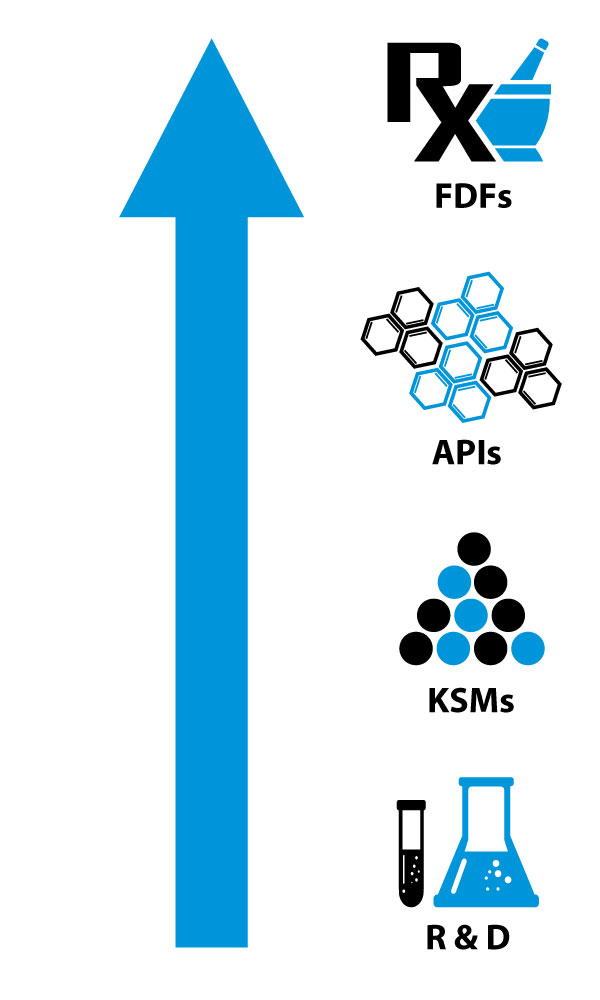

Many of the generic medications Camber Pharmaceuticals offers in the United States are vertically integrated, from KSMs to APIs to FDFs. Camber products have consistent quality and reliable supply channels, helping reduce supply interruptions and mitigate risk.

Vertical integration is a business strategy that involves controlling all aspects of the production process, from the sourcing of raw materials to the distribution of finished products. This strategy can offer several benefits to our customers:

-

Consistent Supply

-

Top Quality Products

-

Competitive Pricing

-

Outstanding Service

Hetero’s Vertical Integration Model

Hetero, Camber Pharmaceuticals’ parent company, invested in vertical integration 30 years ago. Hetero has an extensive network of research and development teams, production facilities, and distribution channels to ensure its Vertical Advantage benefits our customers and patients. Hetero has its own:

Hetero, Camber Pharmaceuticals’ parent company, invested in vertical integration 30 years ago. Hetero has an extensive network of research and development teams, production facilities, and distribution channels to ensure its Vertical Advantage benefits our customers and patients. Hetero has its own:

-

Key Starter Material (KSM) Manufacturing

-

Active Pharmaceutical Ingredient (API) Plants

-

Finished Dosage Formulation (FDF) Facilities

Hetero also has secure supply chains for its excipients, fillers, coatings, capsules, and packaging materials, further reducing supply interruptions.

Safety in Numbers

Camber maintains a 12-month supply of all vertical products in some stage of manufacturing, transit, or storage. Camber has maintained a 99% service level for the past 5 years, generally with at least 3-months of safety stock in our US warehouses for all vertical products.

In addition to safety stock, there is generally two month’s supply in transit to a Camber warehouse, four months of new product in some stage of manufacturing (FDF & API), and three months of raw materials and API being staged for production at a Hetero facility.

-

3+ Months of Product on the Shelf

-

2+ Months of Product en Route to Camber

-

4+ Months of Product in Manufacturing (API & FDF)

-

3+ Months of Product materials being staged

-

12+ Months of Supply Chain Control